A technology for the production of fully domestic endoprostheses has been developed in St. Petersburg

A huge number of hip replacement surgeries are performed in Russia every year. Despite significant advances in the development and use of implants, there is a constant need to improve their long-term effectiveness. The success of joint replacement surgeries is largely determined by the postoperative period when osseointegration occurs. During this process, bone grows into the surface of the implant. This strong bond is necessary to restore the patient’s range of motion. The implant coating must fulfill several conditions: biocompatibility and absence of immune response, promotion of osteoblast growth on the implant surface, attraction of stem cells from surrounding tissues and mechanical stability under physiological loads. For this purpose, scientists are looking for an optimal method of applying porous coatings on the implant surface.

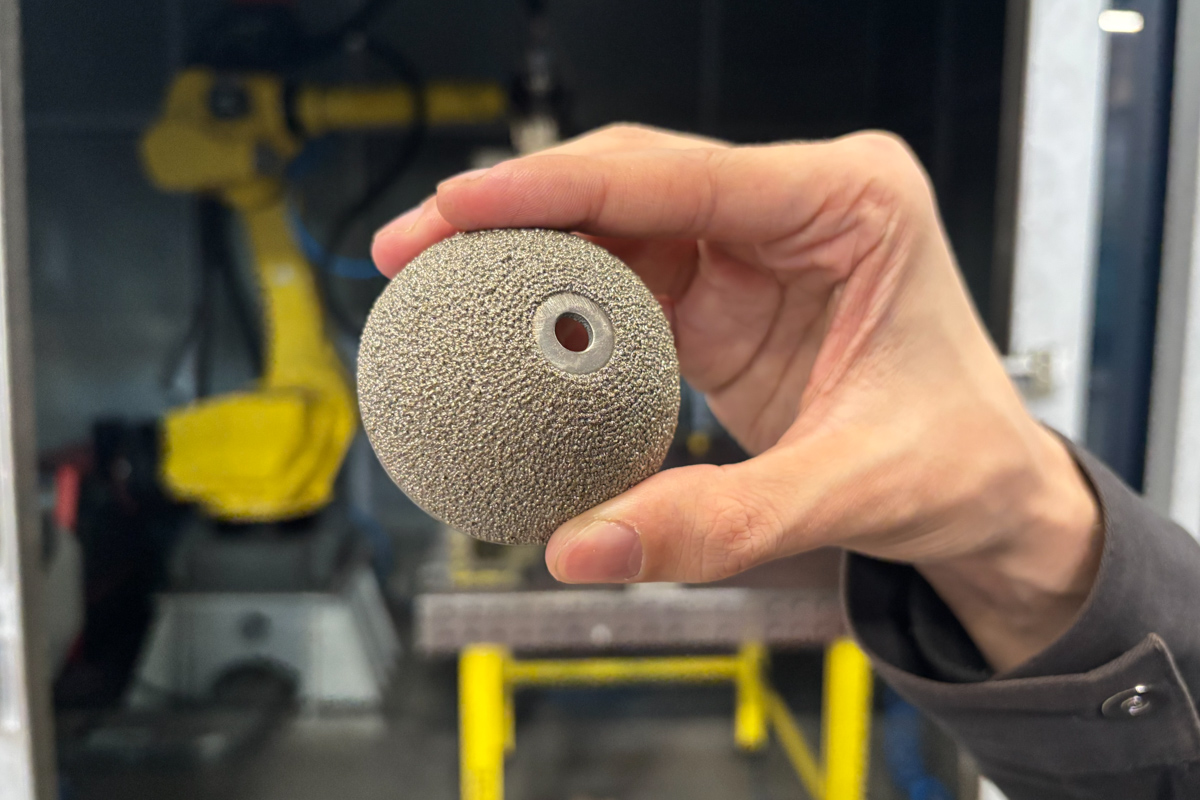

Existing methods of coating implants have some limitations, such as insufficient biocompatibility, low mechanical strength or limited integration with surrounding tissue. Most commonly, biocompatible cement is used to bond the implant to the bone tissue, but in some cases this can lead to limited bonding of the bone-implant pair. SPbPU engineers are working on a technology that allows the implant and bone tissue to bond without cement. For this purpose, open porous structures are formed on the surface of the prosthesis: the bone literally grows into it.

Specialists of the Laser and Additive Technologies Research Laboratory of the Institute of Mechanical Engineering, Materials and Transport of SPbPU have developed a technology of cladding porous coating with a layer thickness of 600 microns with an open porosity of 60-80% and the ability to control these parameters. At the moment, clinical tests of samples and the process of manufacturing of serial surfacing complex by order of OOO Rutil are underway.

We have developed not only the technology, i.e. the method of manufacturing implants, but we are also creating a device base. In our laboratory we have assembled a mock-up of a laser cladding complex. It consists of a laser head, a powder nozzle and a powder feeder. The laser source is a fiber laser. A programmed nozzle trajectory was used to obtain a porous coating. The advantage of our technology is the ability to control the height of the porous coating and the fraction of open porosity. The cups produced using this technology are of premium class in terms of porous coating quality

, said Mikhail Kuznetsov, Head of the Laser and Additive Technologies Research Laboratory at the Institute of Mechanical Engineering, Materials and Transportation of SPbPU.