Russia’s largest automotive wheels manufacturer to use virtual testbeds

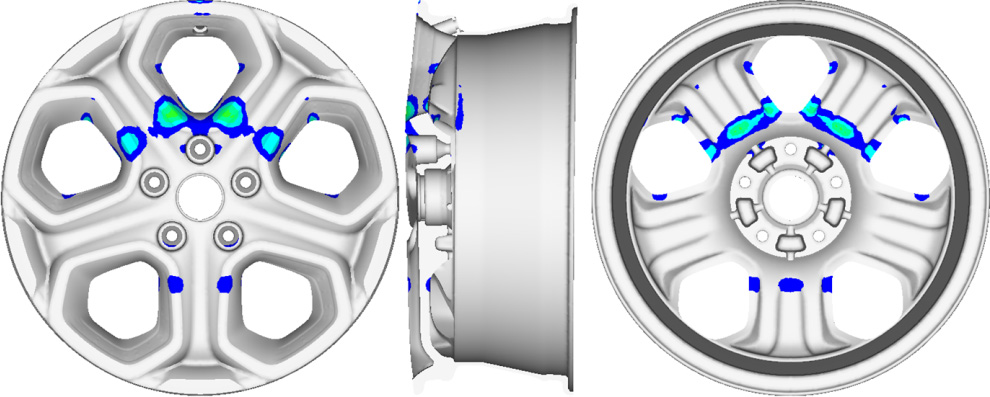

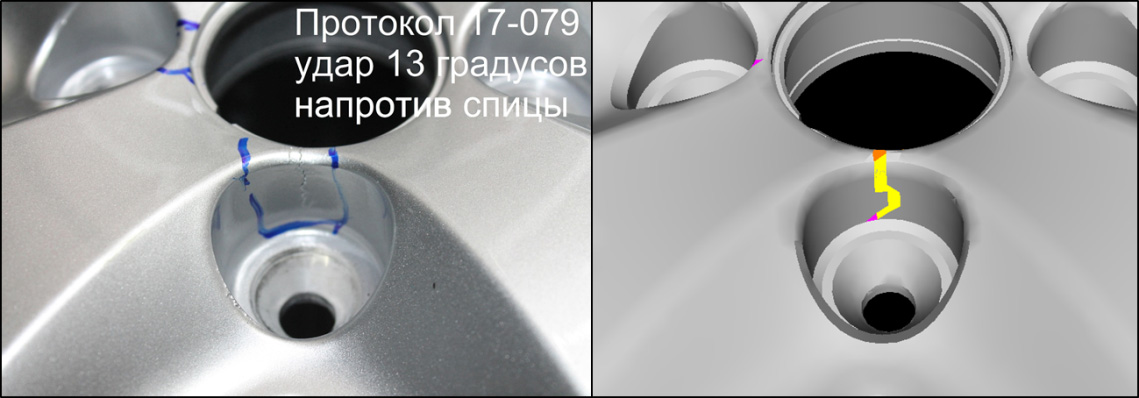

“K & K” LLC, the largest manufacturer of automotive alloy wheels in the Russian Federation, will start using virtual testbeds for its products. This R&D project was carried out by the CompMechLab® Engineering Center, the core of the Advanced Manufacturing Technologies Center of the National Technology Initiative (NTI) of Peter the Great St.Petersburg Polytechnic University (SPbPU). The technology will significantly reduce the number of physical tests. Thus, the cost-efficiency will increase and the time required to launch new products in the market will decrease. Development and release of new wheels models will be now conducted within 2-4 weeks, while previously it took months and even years to launch a new lineup.

“Advanced simulation technologies provide high quality, product reliability and full compliance with the ISO 7141 quality standard used across our industry. At the same time, it helps reduce the cost and duration of new development effort. In collaboration with the Engineering Center of St.Petersburg Polytechnic University we have made a significant step in this direction,” said Anatoly Yermolaev, director of the technology department of “K & K” LLC.

Alexey Borovkov, vice-rector for advanced projects of SPbPU, head of the Advanced Manufacturing Technologies Center of the National Technology Initiative added, “This solution is yet another example of highly adequate computer models of complex products also known as “digital twins”. It is now a key tool to develop globally competitive products for any industry with materials, manufacturing and cost constraints in mind. We have been successfully using these tools for several years now to solve complex high-tech problems for the world’s largest car makers”.