Li-ion battery components to be printed on an inkjet printer

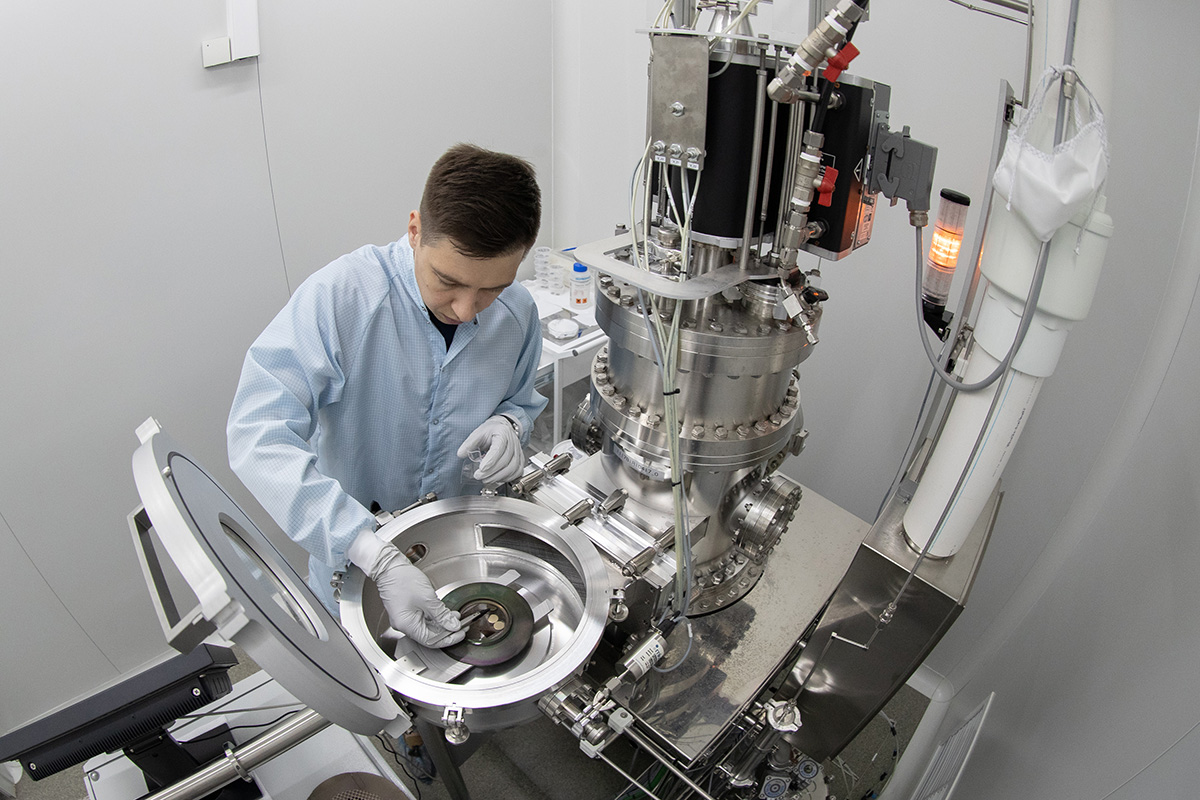

Scientists from Peter the Great St. Petersburg Polytechnic University are developing a technology for printing the electrodes for miniature li-ion batteries by an inkjet printer. The ongoing research may help to create power supplies for biosensors, wearable electronics, and other miniature devices. The results of the study are published in one of the leading scientific journals Energy Technology. The research was carried out with the financial support of the Advanced Manufacturing Technologies Center of the National Technology Initiative (NTI SPbPU) and two Russian science foundation grants.

Li-ion batteries produced by a conventional technology, have a high energy density, meaning they can store a large amount of it in a small volume. Due to this property, they are often used for miniature devices, such as smartwatches, stylus pens and so on. Nowadays, the advancement in that field reached its technological limit, and a further reduction in size is challenging. Therefore, technology growth requires new approaches for manufacturing of batteries. Among other possible solutions are the methods used in the production of integrated circuits, as well as various printing methods that have an advantage in their high performance.

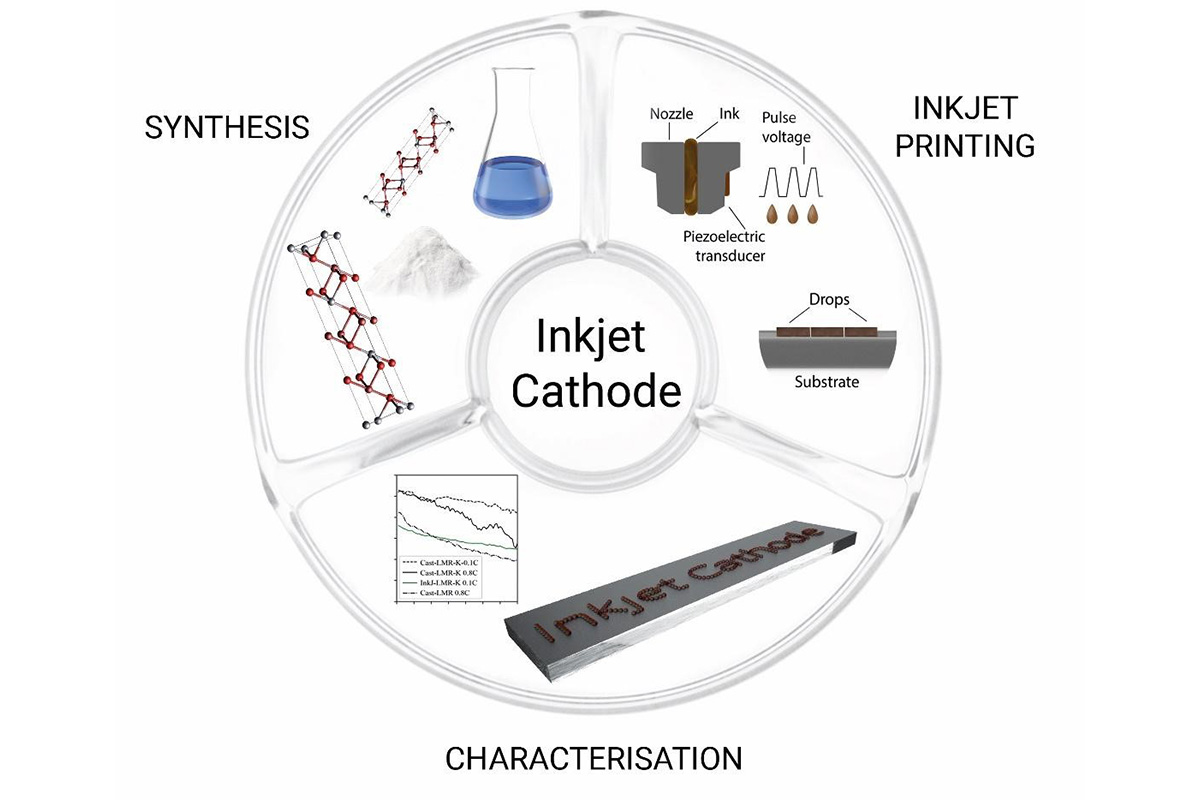

To print electrodes with the given characteristics, one needs to select the synthesis conditions, composition and viscosity of the printing solution, and the printing parameters (for example, the distance between the drops and the number of layers applied). It is a challenging task for specialists from different fields of science. Electrodes manufactured by inkjet printing, cannot provide a sufficiently high energy density compared to electrodes produced by traditional technology. The observed difference is due to the use of various materials, as well as the parameters of the manufactured electrodes – active layer density, the proportion of active material etc.

"To reduce the difference in energy density, we propose to use promising compounds based on lithium and manganese-enriched cathode material with an increased capacity," said Maxim Maximov, PhD in technical sciences, the leading researcher of the Synthesis of new materials and structures laboratory in the National Technological Initiative center "New production technologies" of Peter the Great St. Petersburg Polytechnic University. "We demonstrated the possibility of electrodes manufacturing with this material by inkjet printing. We have also found that the energy intensity of the material in the printed electrode and the electrode made by traditional technology are close".

Using the synthesized active cathode material, the scientists prepared a stable colloidal solution and optimized its rheological parameters for inkjet printing. They selected the conditions for printing electrodes, conducted a study of the electrochemical properties of printed electrodes, confirming the prospects of using the proposed technological approach and the chosen composition of the cathode material. Soon, scientists plan to conduct research, that will provide a further increase in the energy intensity of the printed electrodes and the prototype of the li-ion battery.